Brake maintenance is a critical aspect of vehicle safety that often goes overlooked until it's too late. Worn brakes not only compromise your ability to stop effectively but also pose a significant risk to you and others on the road. Understanding the signs of brake wear and implementing preventative measures can save lives and prevent expensive repairs. This comprehensive guide delves into the intricacies of brake systems, warning signs of wear, and essential maintenance techniques to keep your vehicle's braking performance at its peak.

Understanding brake wear indicators and warning signs

Recognizing the early signs of brake wear is crucial for maintaining vehicle safety. Modern vehicles are equipped with various indicators to alert drivers of potential brake issues. One of the most common is the brake wear indicator, a small metal tab attached to the brake pad that creates a high-pitched squealing sound when the pad material has worn down to a certain thickness. This audible warning is designed to catch your attention before the brakes reach a critical level of wear.

However, not all signs of brake wear are as obvious. Subtle changes in brake pedal feel or vehicle behavior can also indicate potential issues. For instance, a soft or spongy brake pedal may suggest air in the brake lines or a problem with the master cylinder. Conversely, a brake pedal that feels unusually hard or requires more force to engage could indicate a power brake booster failure.

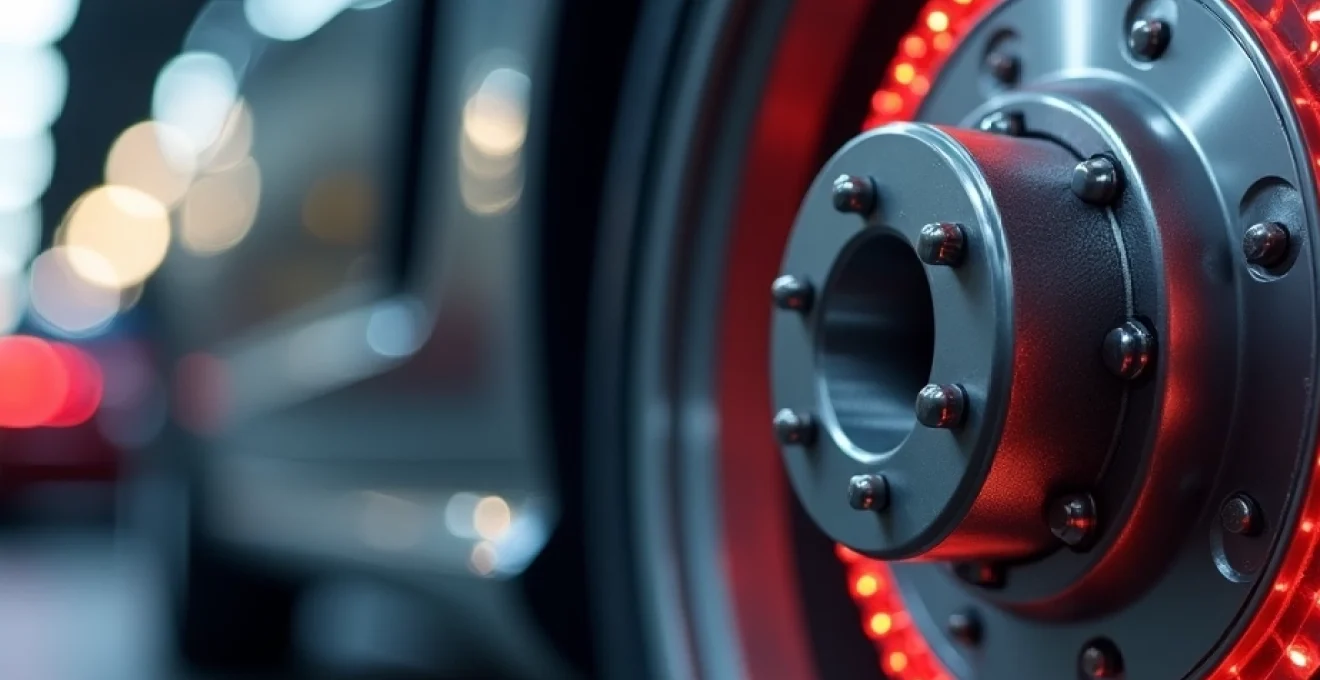

Visual inspections can also reveal valuable information about brake health. Through the wheel spokes, you may be able to see the brake pad material. If it appears to be less than a quarter-inch thick, it's time to consider replacement. Additionally, signs of uneven wear or scoring on the rotor surface can indicate more severe issues that require immediate attention.

Anatomy of brake systems: components most susceptible to wear

To fully appreciate the importance of brake maintenance, it's essential to understand the components that make up a typical brake system and how they interact. The primary components susceptible to wear in most brake systems include brake pads, rotors, calipers, and brake fluid. Each of these plays a crucial role in the braking process and requires regular inspection and maintenance.

Brake pad material composition and lifespan

Brake pads are the workhorses of the braking system, designed to convert kinetic energy into heat through friction. The composition of brake pad material significantly influences its performance characteristics and lifespan. Most modern vehicles use one of three types of brake pad materials: organic, semi-metallic, or ceramic.

Organic pads, composed of materials like rubber, glass, and Kevlar, offer quiet operation and are gentle on rotors but tend to wear faster and produce more dust. Semi-metallic pads, containing 30-65% metal content, provide excellent heat transfer and durability but can be noisier and harder on rotors. Ceramic pads, made from ceramic fibers and nonferrous filler materials, offer a balance of performance, longevity, and low dust production, albeit at a higher cost.

The lifespan of brake pads can vary widely depending on driving habits, environmental conditions, and the quality of the pad material. On average, brake pads may last anywhere from 30,000 to 70,000 miles. However, aggressive driving, frequent heavy loads, or mountainous terrain can significantly reduce this lifespan.

Rotor warping and thickness variations

Brake rotors, also known as discs, work in conjunction with the brake pads to create the friction necessary for stopping. Over time, rotors can develop issues that compromise braking performance. One common problem is rotor warping, where the rotor surface becomes uneven, causing pulsation in the brake pedal and potentially leading to uneven pad wear.

Thickness variations in rotors can occur due to uneven heat distribution or inconsistent material wear. This can result in vibrations during braking and reduced braking efficiency. Regular inspection of rotor thickness and surface condition is crucial for maintaining optimal brake performance.

Caliper piston seal degradation

Brake calipers house the pistons that push the brake pads against the rotors. The piston seals play a critical role in maintaining proper caliper function and preventing brake fluid leaks. Over time, these seals can degrade due to heat exposure and normal wear, potentially leading to brake fluid leaks or caliper sticking.

A stuck caliper can cause uneven brake pad wear and reduced braking performance. Signs of caliper issues include uneven pad wear between the inner and outer pads, or between the left and right sides of the vehicle. Regular inspection and lubrication of caliper slide pins can help prevent these issues.

Brake fluid contamination and boiling point reduction

Brake fluid is a hydraulic fluid that transfers the force from the brake pedal to the calipers or wheel cylinders. Over time, brake fluid can absorb moisture from the air, leading to a reduction in its boiling point. This phenomenon, known as hygroscopic absorption, can significantly impact brake performance, especially under high-stress conditions.

Contaminated brake fluid with a lowered boiling point is more susceptible to vapor lock, where the fluid vaporizes under extreme heat, resulting in a spongy brake pedal and reduced braking efficiency. Regular brake fluid testing and replacement are essential for maintaining optimal brake system performance and safety.

Preventative maintenance techniques for extended brake life

Implementing a proactive approach to brake maintenance can significantly extend the life of your braking system components and enhance overall vehicle safety. By following a few key preventative maintenance techniques, you can avoid costly repairs and ensure reliable braking performance.

Proper bedding-in procedures for new brake pads

When installing new brake pads, the bedding-in process is crucial for optimal performance and longevity. This procedure involves gradually building up heat in the brake system to transfer a thin layer of pad material onto the rotor surface. Proper bedding-in ensures even pad wear, reduces the likelihood of brake judder, and maximizes braking efficiency.

To bed in new brake pads:

- Find a safe, traffic-free area to perform the procedure

- Accelerate to 35 mph and apply moderate brake pressure to slow down to 5 mph

- Repeat this process 8-10 times, allowing a short cooling period between each cycle

- Perform 2-3 more aggressive stops from 55 mph to 5 mph

- Allow the brakes to cool completely before normal driving

This process helps create an even transfer layer on the rotor surface, promoting consistent brake performance and wear characteristics.

Brake fluid flushing and DOT rating selection

Regular brake fluid flushing is essential for maintaining the integrity of your brake system. Over time, brake fluid absorbs moisture from the air, which can lead to corrosion within the system and a reduction in the fluid's boiling point. Most manufacturers recommend flushing brake fluid every two years or 30,000 miles, whichever comes first.

When selecting brake fluid, it's important to choose the correct DOT (Department of Transportation) rating for your vehicle. The most common ratings are DOT 3, DOT 4, and DOT 5.1, each with different boiling points and performance characteristics. Always consult your vehicle's owner manual for the recommended DOT rating and never mix different types of brake fluid.

Rotor resurfacing vs. replacement criteria

When addressing rotor issues, the decision between resurfacing and replacement depends on several factors. Rotor resurfacing, also known as machining, involves removing a thin layer of material from the rotor surface to create a smooth, even braking surface. This can be an effective solution for minor warping or uneven wear, but it's not always the best option.

Criteria for rotor replacement include:

- Thickness below the manufacturer's minimum specification

- Severe scoring or grooving that cannot be removed by machining

- Visible cracks or heat checking on the rotor surface

- Previous machining that has reduced the rotor thickness close to the minimum specification

In many cases, especially with modern vehicles that use thinner rotors, replacement may be more cost-effective and provide better long-term performance than resurfacing.

Caliper cleaning and lubrication best practices

Regular cleaning and lubrication of brake calipers can prevent sticking and ensure smooth operation. When servicing brakes, it's important to clean the caliper slide pins and apply a high-temperature brake lubricant to allow free movement. This prevents uneven pad wear and ensures the caliper can fully release when the brake pedal is not applied.

Additionally, inspecting the rubber boots and seals on the caliper for damage or deterioration is crucial. These components protect the internal parts of the caliper from contamination and moisture. If any signs of wear or damage are present, replacement of these components is recommended to prevent more serious issues down the line.

Advanced diagnostic methods for early wear detection

Modern automotive technology has introduced advanced diagnostic methods that can detect brake wear and potential issues before they become critical. These methods go beyond traditional visual inspections and can provide valuable insights into the health of your braking system.

One such method is brake pad wear sensors, which are integrated into the brake pad and provide an electrical signal to the vehicle's computer when the pad material reaches a certain thickness. This technology allows for real-time monitoring of brake pad wear and can alert the driver well before the pads reach a critical level.

Another advanced diagnostic tool is thermal imaging, which can be used to detect uneven heat distribution across brake components. This method can reveal issues such as stuck calipers, worn wheel bearings, or unevenly worn pads that might not be immediately visible during a standard inspection.

Digital brake fluid testers are also becoming more common in professional repair shops. These devices can accurately measure the moisture content and boiling point of brake fluid, providing a more precise determination of when fluid replacement is necessary compared to visual inspection alone.

Impact of driving habits on brake longevity

Your driving habits play a significant role in determining the lifespan of your vehicle's braking components. Aggressive driving techniques and certain traffic behaviors can accelerate brake wear and lead to premature failure of brake system components.

Effects of aggressive braking and tailgating

Aggressive braking, characterized by frequent hard stops and sudden deceleration, places excessive stress on brake components. This driving style not only wears brake pads and rotors more quickly but also generates more heat, which can lead to brake fade and reduced braking efficiency.

Tailgating, or following too closely behind another vehicle, often results in more frequent and harder braking. This habit not only increases the risk of collision but also contributes to accelerated brake wear. Maintaining a safe following distance allows for more gradual braking and reduces the overall strain on your brake system.

Mountain driving techniques to reduce brake strain

Driving in mountainous terrain presents unique challenges for your vehicle's braking system. The constant use of brakes on long downhill stretches can lead to overheating and brake fade. To mitigate this, it's important to use proper mountain driving techniques:

- Engage a lower gear to use engine braking

- Use the brakes intermittently rather than continuously

- Plan ahead and reduce speed before steep descents

- Take advantage of runaway truck ramps if brake failure occurs

These techniques help distribute the workload between the engine and brakes, reducing the risk of overheating and maintaining more consistent braking performance throughout the descent.

Optimal brake temperature management in performance driving

For those engaged in performance driving or track events, managing brake temperature is crucial for maintaining consistent braking performance. High-performance driving generates significant heat in the braking system, which can lead to brake fade if not properly managed.

Techniques for optimal brake temperature management include:

- Using high-temperature brake fluid designed for performance applications

- Installing brake cooling ducts to direct air to the rotors

- Allowing for cool-down laps between high-speed runs

- Monitoring brake temperatures with pyrometers or thermal imaging

By implementing these strategies, performance drivers can maintain more consistent brake performance and extend the life of their braking components under high-stress conditions.

Upgrading brake components for enhanced safety and durability

For those seeking improved braking performance or facing challenging driving conditions, upgrading brake components can provide enhanced safety and durability. However, it's important to approach brake upgrades thoughtfully, considering the entire system rather than individual components in isolation.

When considering brake upgrades, evaluate the following options:

- High-performance brake pads with improved heat resistance and friction characteristics

- Slotted or cross-drilled rotors for better heat dissipation and pad deglazing

- Stainless steel braided brake lines for improved pedal feel and resistance to expansion

- Larger diameter rotors and multi-piston calipers for increased stopping power

It's crucial to ensure that any upgrades are compatible with your vehicle's existing brake system and that they meet or exceed the original equipment specifications. Consulting with a professional brake specialist can help you make informed decisions about which upgrades will provide the most benefit for your specific driving needs.

Remember that upgrading one component often necessitates upgrading others to maintain system balance. For example, installing larger rotors may require new calipers and wheels to accommodate the increased size. Always consider the entire braking system when planning upgrades to ensure optimal performance and safety.

By understanding the intricacies of brake wear, implementing preventative maintenance techniques, and making informed decisions about potential upgrades, you can significantly enhance the safety and longevity of your vehicle's braking system. Regular inspections, timely repairs, and attention to driving habits all contribute to maintaining optimal brake performance and preventing dangerous accidents and costly repairs.